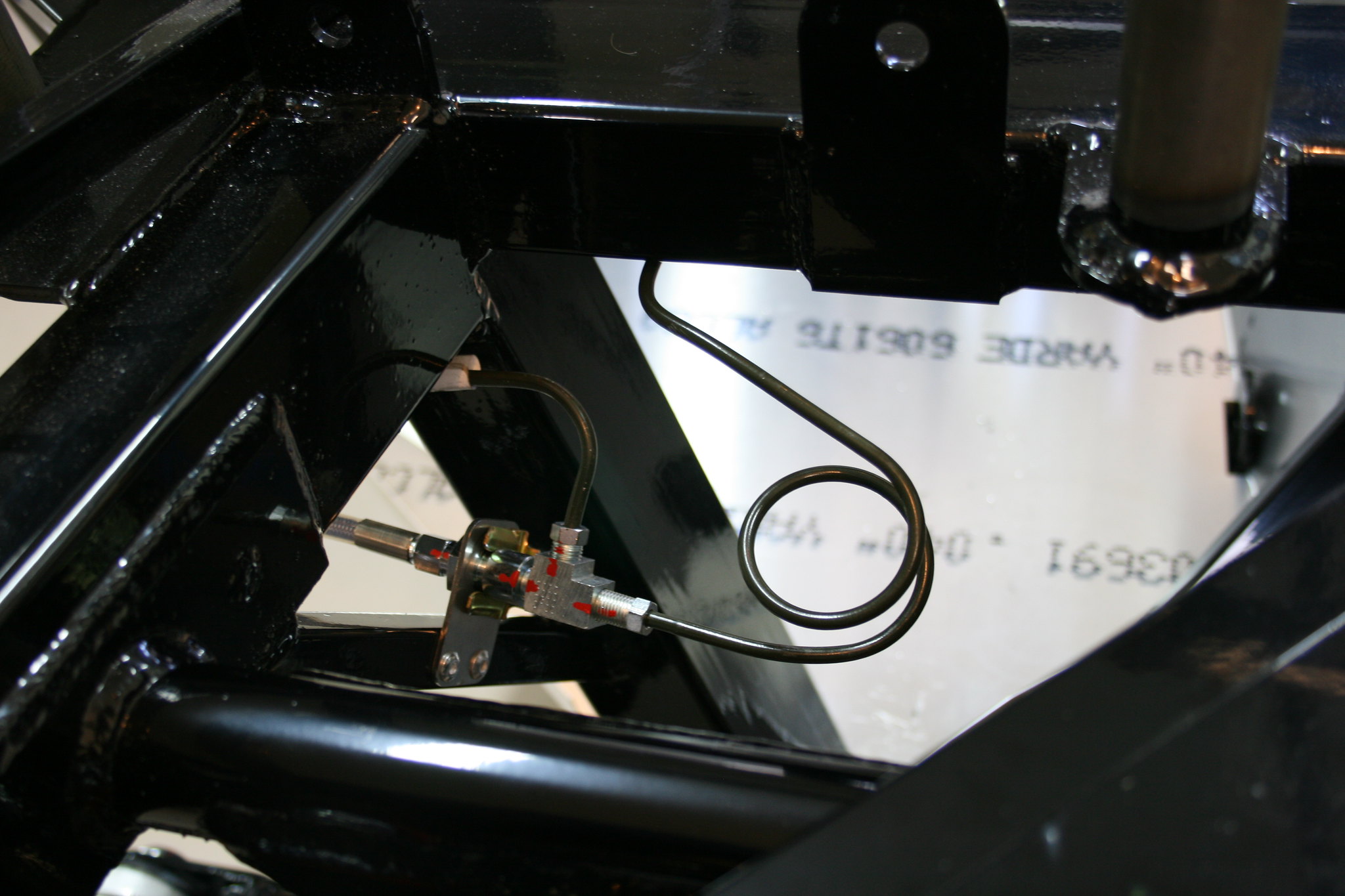

Next it was on to plumbing the brake lines. 3/16" brake line is much easier to bend than the steel fuel line was. I pretty much stuck to the book on this portion. Trying to hide the lines as best I could. Once I had all the hard line bent and connected. I filled the system and started bleeding the brakes. No major leaks anywhere, small leaks at the master cylinders went away after tightening the fittings just a bit more.

Brake pedal feels pretty solid for now, but once I take that first test drive I'll know how well I bled the brakes.

Chronicling the saving, searching, purchasing, assembling, and driving of a Shelby Cobra Replica from Factory Five Racing (MK4).

Monday, December 15, 2014

Plumbing

With the alignment roughly complete I moved on to the plumbing. This is one place where I deviated a bit from the plan. I ended up buying some 3/8" diameter steel hose for the fuel line instead of using the supplied 5/16". I also -6 PTFE steel braided fuel hose for all the flexible pieces. Since I wasn't using much of what was supplied, I also had to buy a whole bunch of fittings. I also decided on an external electric fuel pump (Mr. gasket P95 or 95P). There really no designated place to mount the fuel pump so I made a bracket, painted it, and bolted it to the frame near the rear end.

Anyway once I found suitable places to mount the fuel filters and fuel pump I started bending the steel tube. I went through 2 sets of cheap tubing benders from O'reilly before I decide it was just going to be easier to bend by hand. Luckily I only had to make around 4 bends to get it shaped right.

Anyway once I found suitable places to mount the fuel filters and fuel pump I started bending the steel tube. I went through 2 sets of cheap tubing benders from O'reilly before I decide it was just going to be easier to bend by hand. Luckily I only had to make around 4 bends to get it shaped right.

Subscribe to:

Comments (Atom)